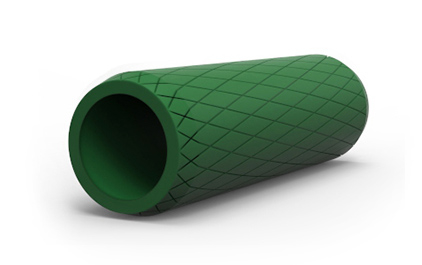

Our mandrel sleeves

For the aluminium, steel & stainless steel industry

Hannecard offers a unique range of elastic rubber & polyurethane mandrel sleeves, for all mandrel types & sizes. Available in thicknesses between 4mm & 120mm, our mandrel sleeves come in all possible finishes: smooth or rough finish, inside or outside bevels & with different groove patterns including diamond, spreader, axial & rhombic (for a better water & oil release).

Hannecoil-S

- Standard option for un- and rewinding coils

- Good cut & wear resistance

Hannecoil-D

- Preferred option for rewinding coils

- Maximum reduction of coil damage (broken strip effect)

- Good cut & wear resistance

Hannecoil-XP

- Preferred option for unwinding coils

- Excellent cut & wear resistance

Our elastomer characteristics

- Good shape-stability & mechanical resistance

- Outstanding shrinking & expansion behavior

- Excellent resistance to protective oils & grease

- Permanent elasticity

- Perfect behavior in dilatation & shrinking

- High durability

Our rubber sleeve benefits

- Reduce scrap due to the inner-winding of the coil

- Maintain friction between mandrel surface & sleeve

- Eliminate head end breaks & marks

- Avoid telescoping during winding

- Improve grip between sleeve & coil

Our services

- Tailor-made solutions

- The highest quality rubber & polyurethane compounds

- Technical advice on choice of materials, hardness & dimensions

- Deformation calculation based upon customer traction values

- Advice on exterior & interior finish specifications

- Customer follow-up regarding performance & lifetime

- Quick & worldwide delivery